Savings Tools

How to Design a Cost Effective Stamping

Stamping

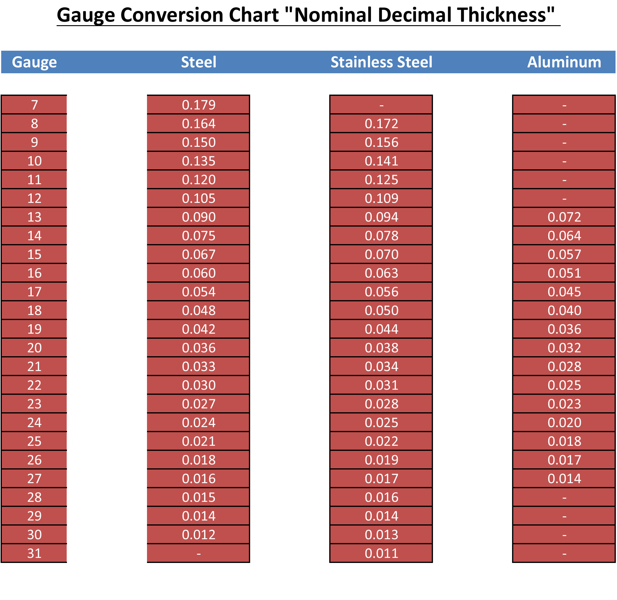

Metal stamping is the process of shaping parts by using a tool set that punches or stamps holes and shapes into a metal sheet. This process can be a very fast, efficient and cost effective process to form many types of parts from a wide variety of metals. Intricate part designs, strength, durability, wear resistance, and repeatability are common benefits of stamping. When selecting a stamping process, over-specifying a steel grade and blank thickness are major factors to drive up the cost of metal stamping. There are many material choices that will respond well to the metal stamping and forming processes. However, the price and availability can vary in a wide range, so it has significant impact on the cost and delivery of production.

Progressive stamping

One cost saving operation of metal stamping is called progressive stamping which applies at least three stamping operations with one machine. An example of this is one that involves punching, coining, and bending. This is done in alternating patterns, producing one part after another in seconds, thus increasing efficiency and saving time, which in turn saves money.

Piercing

Piercing, one of the most widely used metal stamping operations, produces usable shapes from a metal strip or sheet, discarding the punched-out portions and instead using whatever is left of the metal web. An example is shown below in its simplest form of a piercing operation, including perforating and notching.

Piercing of all holes is best done together to ensure good hole-to-hole tolerance and part repeatability. However if the material distorts, the method described below can be done. When there are large numbers of holes, in a tight pitch, there could be distortions, due to the high amount of tension on the upper surface and stretching and compression on the bottom surface. This causes the material not to lay flat. This can be avoided/lessened by staggering the piercing of the holes. Holes are punched in a staggered pattern; then the other holes are punched in the alternate staggered pattern.

Design Tips

- Minimum hole diameter should be at least 20 % greater than stock thickness. When using stainless steels, it should be 2 times the material thickness.

- Minimum wall thickness (distance from hole to edge or hole to hole) should be at least 2 times stock thickness.

- For non-round slots, the minimum wall thickness should be 2 times thickness for short slots < 10 thicknesses long; and 4 times thickness for long slots > 10 thicknesses long.

- Minimum hole (and short slot) to bend distance should be 2.5 × the stock thickness + bend radius.

- For long slots, the distance should be 4 × the stock thickness + bend radius.

- “Spring back” is different for different materials (i.e. stainless steel generally has to be bent further than carbon steel as it has higher “spring back” properties.

Argo Products Company is a low cost ISO 9001 value added, custom manufacturer of complex metal products using combined CNC Wire Formed, Stamped, Robotic Welded Assembly Solutions including Kitting, Pa..

Read MoreQuick Links

About Us Services Our Projects Certifications & Associations Wire Forming Metal Fabrication News Quality Assurance Job Opportunities Supply Chain Inventory Management Supplier Restricted Material Contact Us Privacy Policy© 2025. Argo Products Company, All Right Reserved. Industrial Website Design - WYSIWYG Marketing