Our Services

Wire Forming Services

Capabilities

| General Capabilities | Contractor OEM Sub-Contractor |

| Fabrication Process | Bending CNC Cold Headed Cutting Drawing Flattening Milling Pointing Rolling Straightening Stretching Swaging Tapping Threading Welding |

| Equipment List | (1) Hydraulic bender (2) Auto feed wire forming presses (3) Straighten and cut machines (4) Pneumatic benders (8) Computer Numerical Controlled (CNC) wire forming machines |

| Maximum Wire Diameter | CNC 5/8 Inch Non-Automatic 1.0 Inch |

| Tolerance (+/-) | Depends on Products But Typically 0.010 to 0.030 Inch |

| Design Capabilities | AutoCAD (DWG) JPG SolidWorks |

| Additional Services | Assemblies Engineering Inventory Mangement Production Prototype |

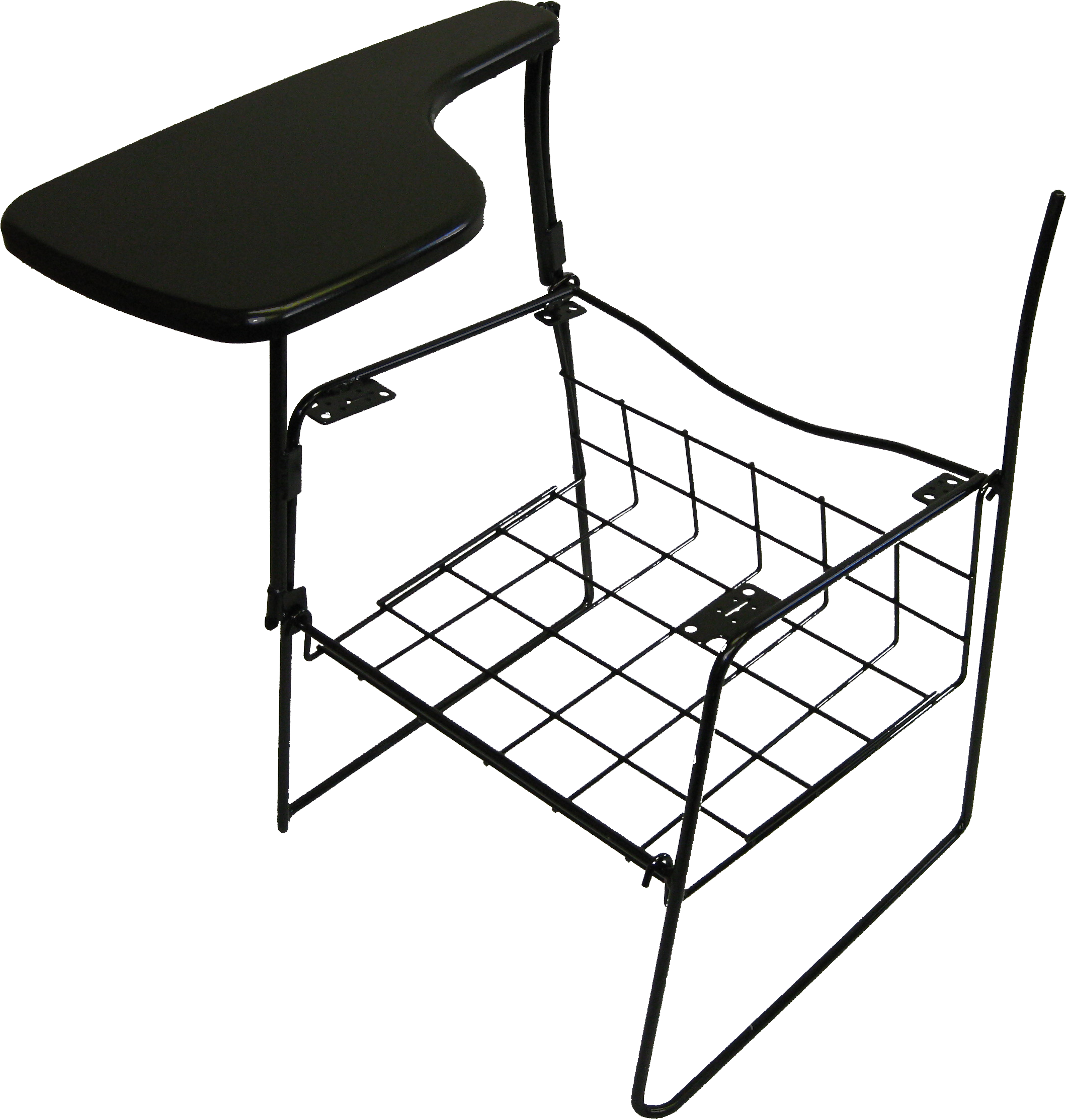

| Industry Focus | Agricultural Lawn & Garden Medical Metal Chair Metal Chair & Furniture Transportation |

| Certifications | ISO 9001 Certificate |

Wire Forming Services Fabrication Process

Wire Threading Fabrication

Wire Forming Bending

Wire Forming CNC

Wire Forming Welding

Wire Forming Straightening

Wire Drawing

Wire Forming Services FAQs

What is Argo great at producing?

Can Argo make product to "concept design" and/or "finished print" specifications?

What is Argo policy regarding "Quality"?

What are the major markets Argo serves?

What quality objectives for continuous improvement does Argo measure?

What is Wire Forming

Related Projects

Certifications

Wire Forming Equipment

- 5 – Six Axis High Speed Robotic CNC Wire benders ranging in capacity up to 5/8" diameter material

- 3 – Two Axis High speed robotic CNC Wire benders & butt welding machines ranging in capacity up to 1/8" diameter material

- Greater than 5/8" diameter on other machinery

Wire Forming Services

Argo Products specializes in precision wire forming services, offering a wide range of capabilities to meet diverse needs. Their skilled professionals use state-of-the-art equipment to create custom wire components and springs, handling projects of all sizes with attention to detail. Collaborating closely with clients, Argo tailors its wire forming services to specific requirements, ensuring innovative solutions. The company's expertise spans various industries, maintaining high standards of craftsmanship, durability, and functionality. Prospective clients can explore Argo's comprehensive capabilities on their service page to discover how they can address unique wire forming needs with precision and expertise.

© 2025. Argo Products Company, All Right Reserved. Industrial Website Design - WYSIWYG Marketing